In the dynamic world of manufacturing and design, precision and efficiency are not just goals—they are imperatives. At Laserworx Manufacturing, we understand this need acutely, which is why we’ve embraced the remarkable advancements in laser tube cutting in Oxnard & Los Angeles. This evolution is not just about enhancing our capabilities; it’s about transforming your projects, making them better, faster, and more cost-effective. Our laser tube cutting services in Los Angeles are designed to meet the high demands of this ever-evolving industry.

Precision and Complexity Redefined with Laser Tube Cutting in Oxnard & Los Angeles

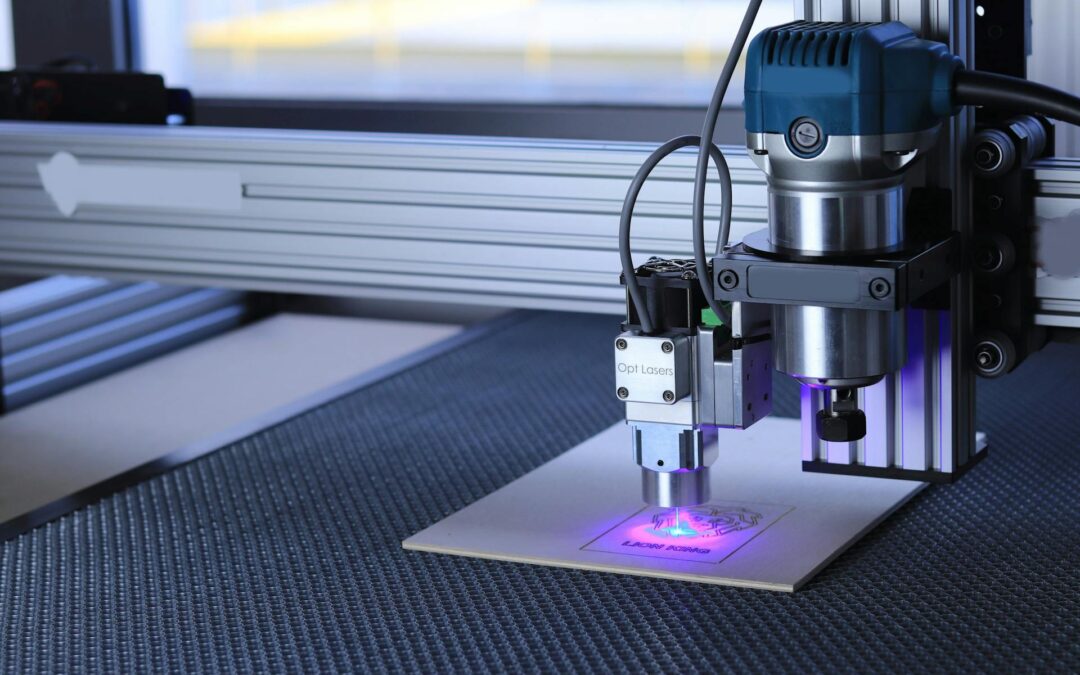

Gone are the days when achieving intricate designs was a challenge due to the limitations of early laser cutting technologies. The leap in precision now allows for complex cuts and elaborate patterns that were once deemed unattainable. At Laserworx Manufacturing, this means your projects can now include more detailed and precise outcomes, significantly enhancing the quality of the final product. Whether it’s a delicate piece of art or a complex mechanical part, we ensure that every cut is a testament to unmatched precision.

Speed and Efficiency: The Fast Track to Completion with Laser Tube Cutting in Oxnard and Los Angeles

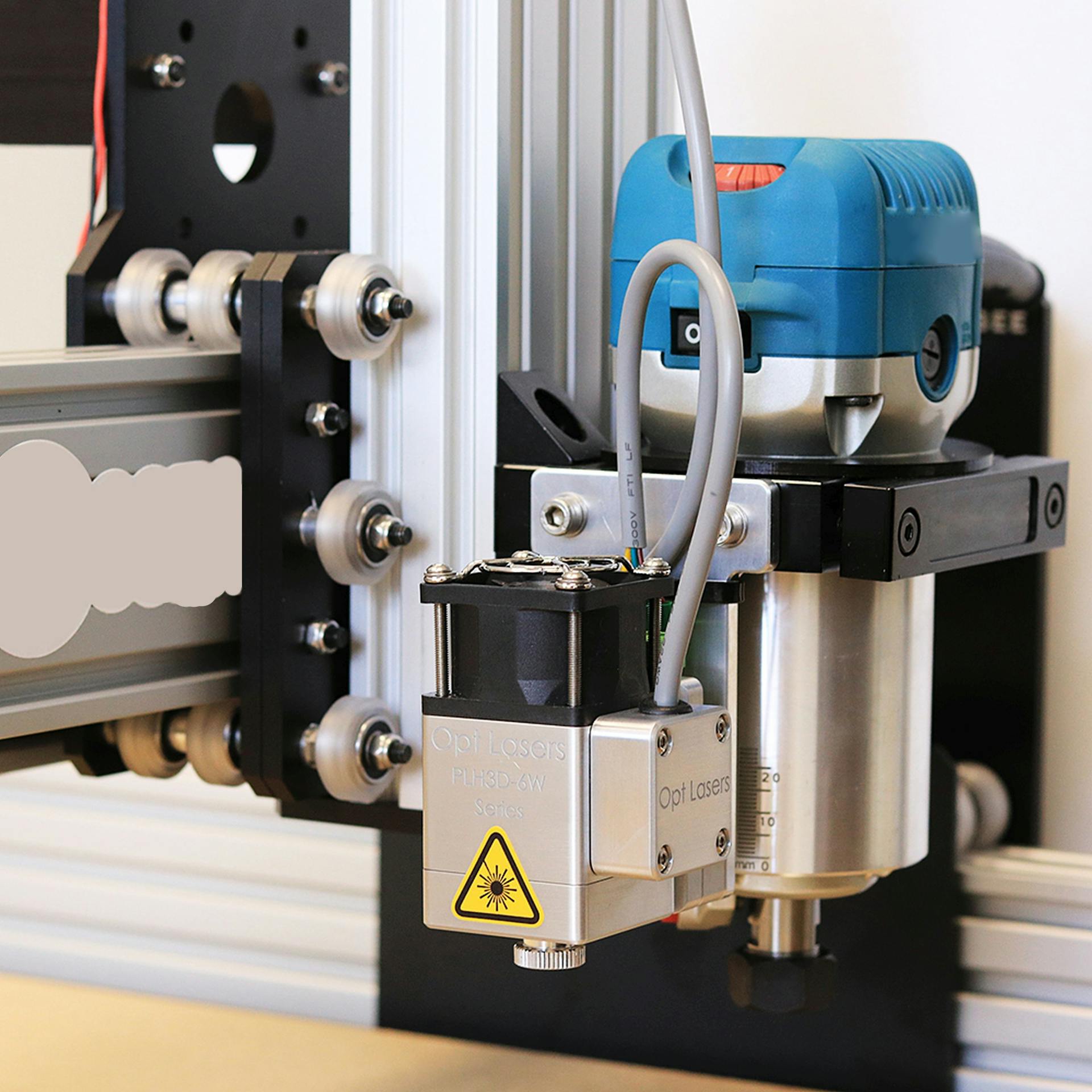

The introduction of fiber lasers and advancements in CNC machinery have revolutionized laser tube cutting in Oxnard & Los Angeles, making the process not just faster but more energy-efficient. For our clients, this translates to quicker project completions, reduced lead times, and enhanced productivity. Laserworx Manufacturing is at the forefront of utilizing these advancements, ensuring that your projects are delivered efficiently without sacrificing quality, meeting your deadlines every time.

Material Versatility: Expanding the Realm of Possibilities with Laser Tube Cutting in Oxnard and Los Angeles

One of the most exciting developments in laser tube cutting technology is the ability to work with a broader range of materials. From metals to plastics and composites, modern laser tube cutting machines can handle diverse material requirements with ease. This versatility opens up new possibilities for clients across various industries, including aerospace, automotive, and custom furniture. No matter the material or the thickness, Laserworx Manufacturing is equipped to bring your vision to life.

Sustainability and Cost-effectiveness: A Greener Approach with Laser Tube Cutting in Oxnard and Los Angeles

Today’s laser tube cutting technology is not just about efficiency and versatility; it’s also about sustainability. The advancements have made the process more energy-efficient and reduced waste production, aligning with our commitment to environmentally responsible manufacturing practices. For our clients, this means cost savings and the peace of mind that comes from choosing a sustainable manufacturing process.

Empowering Your Projects with Laserworx Manufacturing

At Laserworx Manufacturing, we are excited about the possibilities these technological advancements bring to your projects. We invite you to explore how our laser tube cutting services can elevate your next project. Schedule a consultation with us to discuss your specific needs and how we can offer tailored, cutting-edge solutions that make your ideas a reality.