Tube Processing

Tube Processing & Forming Made Easy for Ventura County Area Clients

At Laserworx Manufacturing, we handle tube processing services reduce or eliminate punching, drilling, sawing, or deburring processes. Our friendly team of experts will always furnish you with finished parts in a wide range of sizes with unprecedented accuracy and lightning fast turnaround times. With a reputation for friendly customer service & quality results, Laserworx Manufacturing is proud to help clients across all industries throughout Oxnard and the entire Ventura County area.

The Latest Equipment for the Best Results

Utilizing two Conrac Eaton Leonard mandrel bending machines (2” and 4”) coupled with various die sets ranging from 1” to 4” diameter tubing, we can bend a large range of tubing of various sizes, thickness, & material types.

We also use a Mittler Brothers’ rotary bender for very fast prototype bending where the bend tolerance is not as critical, getting you faster results.

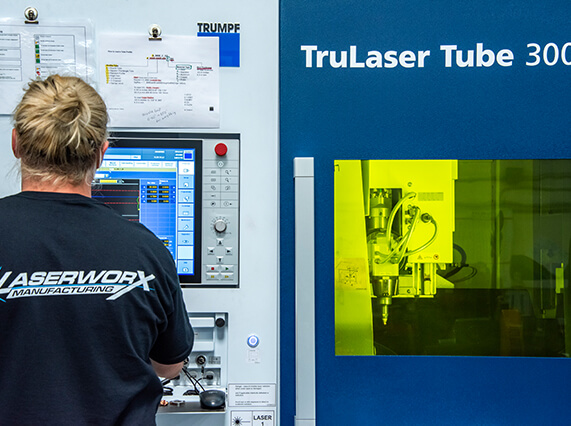

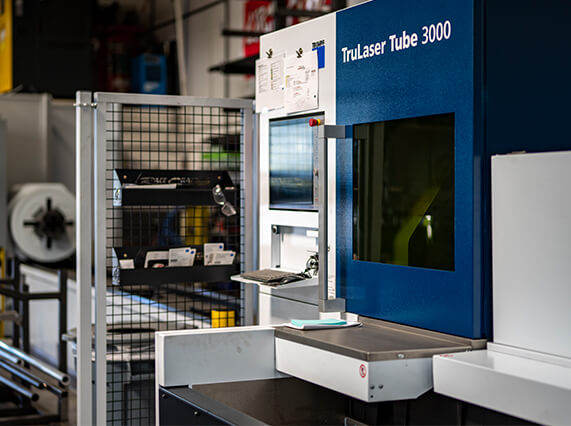

Utilizing a brand-new state-of-the-art Trumpf Fiber Tube laser, we can process up to 6″ diameter tubes from rectangles, squares, c-channels, round, & other tubing shapes. We also have you covered with all types of materials including stainless, aluminum, steel, copper, & titanium. Using a series of mandrel bending and tube rolling machines, we can always form highly accurate shapes.

Custom CNC Tube Cutting Machine

Two Conrac Mandrel Tube Bending Machines

Trulaser Tube 3000 Fiber

These machines ensure high-quality cutting data that produces nothing but high quality cuts. We’re able to deliver high dynamics and efficient cutting times that expedite material at a rapid rate without sacrificing quality. Our machines allow us to process all types of tube structures including:

- Race Vehicles

- Space Frames

- Air Flight Applications

Watch Our Videos

Call Us Today to Learn More

Conveniently located in Oxnard, Laserworx Manufacturing has been helping Ventura County residents with all types of precise, high-quality tube processing for years. Family owned & operated, our hands-on owner & engineering team will work with you to make sure your next project is your best one. Please call or visit us today to learn more or with any questions for our friendly team.