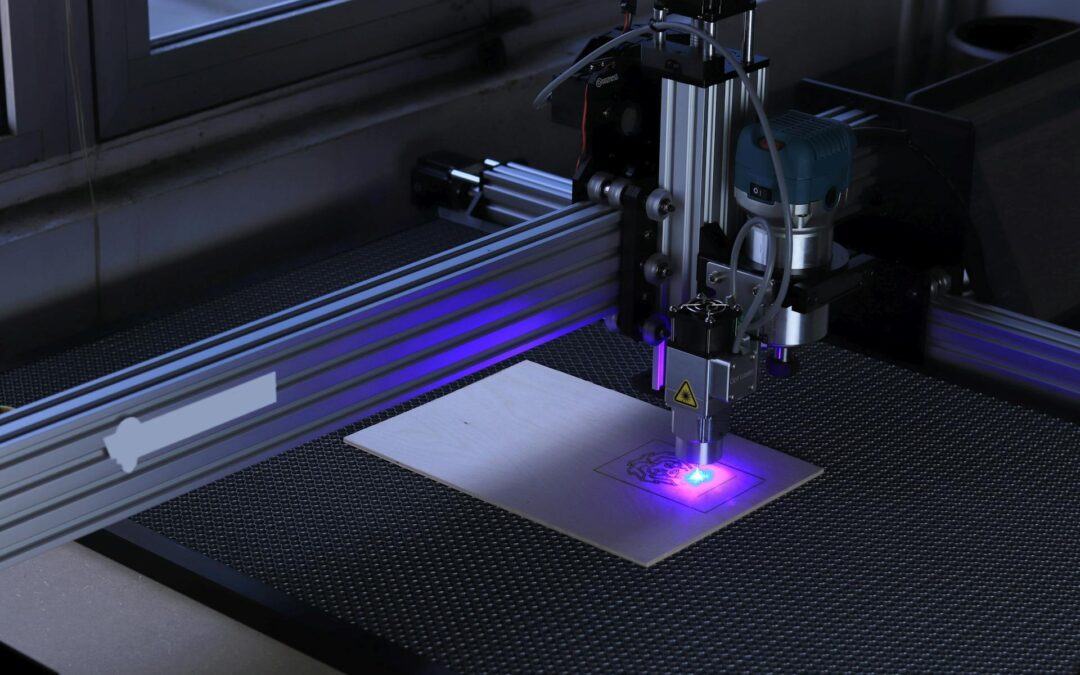

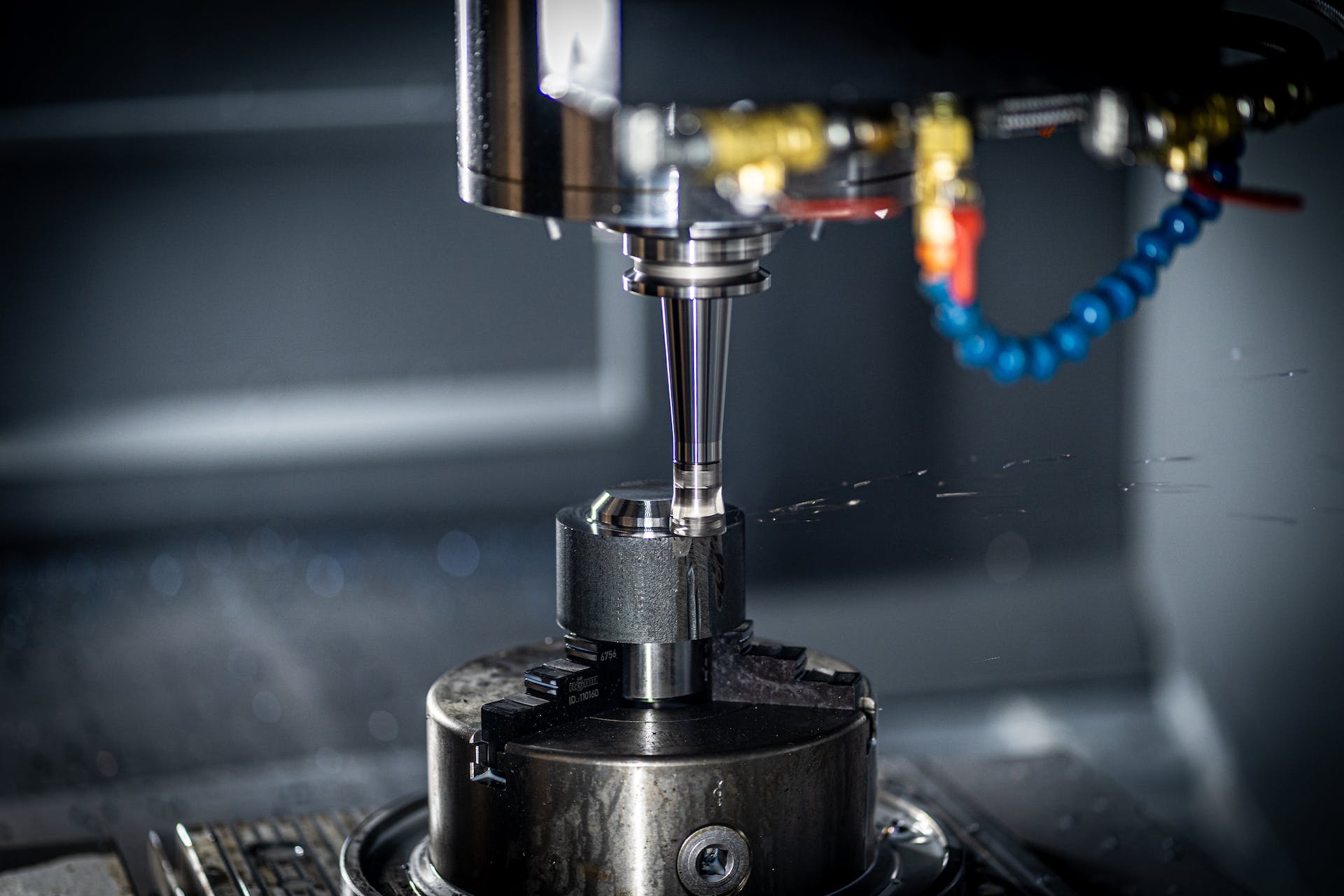

Laser Tube Cutting vs. Traditional Cutting Methods: Enhancing Efficiency and Precision

In the evolving landscape of manufacturing and design, the quest for more efficient, precise, and cost-effective methods of production is never-ending. Among the various technological advancements, laser tube cutting has emerged as a frontrunner, significantly outperforming traditional cutting methods. Laserworx Manufacturing is at the forefront of this innovation, offering cutting-edge laser tube cutting services that meet the demanding needs of modern industries. Let’s delve into a comparative analysis of laser tube cutting and traditional methods, focusing on the key benefits of embracing laser technology.

Unparalleled Precision and Intricacy

Laser tube cutting stands out for its exceptional precision, which traditional cutting methods struggle to match. This advanced technology allows for intricate cuts and detailed patterns that would otherwise be impossible or time-consuming with conventional methods. The ability to produce complex designs with high accuracy not only enhances product quality but also reduces the need for secondary finishing processes, saving both time and money.

Moreover, the precision of laser cutting minimizes errors and inconsistencies, ensuring that every piece meets stringent quality standards. This level of accuracy is particularly crucial in industries where even minor discrepancies can significantly impact the functionality and safety of the final product.

Speed and Efficiency Redefined

The efficiency of laser tube cutting is another major advantage over traditional methods. Thanks to the automation and speed of laser technology, production times are drastically reduced, allowing for faster project completion and increased throughput. This efficiency is a game-changer for manufacturers facing tight deadlines or looking to scale up their production without compromising quality.

Additionally, the speed of laser cutting does not sacrifice precision. Manufacturers can enjoy the best of both worlds — rapid production and meticulous accuracy, enabling them to stay competitive in fast-paced markets.

Material Efficiency and Sustainability

One of the less discussed but equally important benefits of laser tube cutting is its contribution to material efficiency and sustainability efforts. Laser cutting minimizes waste by maximizing the use of materials, thanks to its precise cutting capabilities. This not only reduces material costs but also aligns with sustainability practices by decreasing scrap and promoting efficient use of resources.

In an era where environmental responsibility is increasingly prioritized, adopting technologies that support these values can enhance a company’s reputation and appeal to eco-conscious consumers.

Cost-Effectiveness in the Long Run

While the initial investment in laser cutting technology may be higher than traditional methods, the long-term savings are undeniable. The efficiency and speed of laser cutting reduce labor costs and production times, while the precision of the cuts lowers material waste and eliminates the need for extensive secondary processing.

Businesses that invest in laser tube cutting services find that the technology pays for itself through improved efficiency, reduced waste, and the ability to tackle more complex projects that would not be feasible with traditional methods.

Making the Switch to Laser Cutting

For manufacturers, construction professionals, and designers seeking to enhance their production capabilities and product quality, the advantages of laser tube cutting are clear. Laserworx Manufacturing invites you to explore how our laser tube cutting services can transform your projects. We encourage you to contact us for a consultation or to request a quote, and to visit our website for more detailed information on our services and capabilities.

In the world of manufacturing and design, embracing innovative technologies like laser tube cutting is the key to staying ahead. With its unmatched precision, speed, material efficiency, and cost-effectiveness, laser cutting is not just an alternative to traditional methods — it’s the future. Contact us today!