The advent of computer numerical control (CNC) prototyping gave huge advantages to those who want to quickly and accurately manufacture their best product. The benefits of prototyping are clear, but the use of a CNC machine makes the process faster, makes feedback better, helps you make better decisions about your project design or manufacture, and overall saves money. It’s important for companies, entrepreneurs and others to consider how a CNC lathe can benefit their prototype.

Range of Materials

Using a CNC lathe is not your only option when it comes to prototyping. You can certainly use 3D printing and other methods, but a CNC lathe can create prototypes in a broader range of materials, including metals. The more accurate you can make your prototype, the more valuable the information you get from the prototyping project. So, if you envision a final product in metal, it is important to get a prototype in this material, if only to better understand its quality, function and cost.

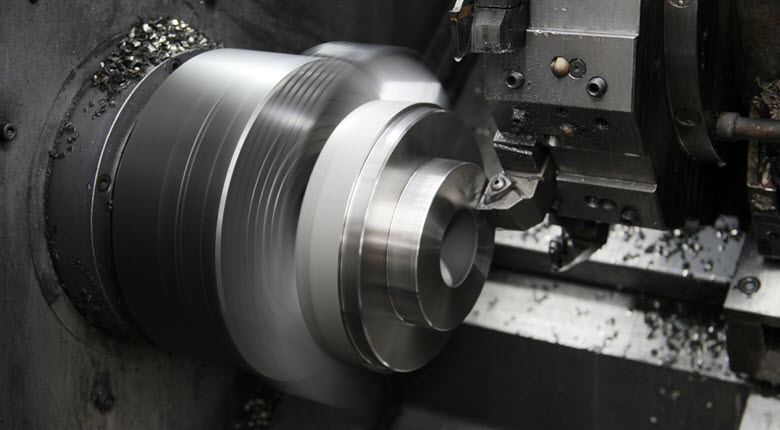

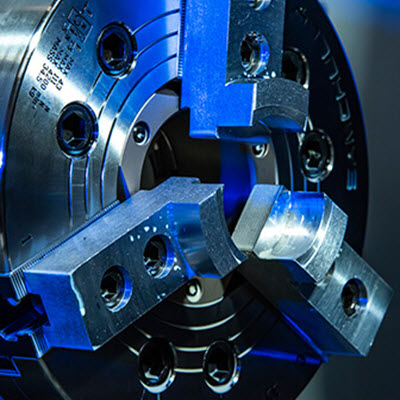

Precision and Details with a CNC Lathe

CNC lathes are computer-guided and make prototypes to a very high threshold of detail. Just as with material choice, these additional details help you ensure that you’re getting the most value from the prototyping process. The more accurate the model, the better your understanding of how a real product will look, work and feel.

Customer Opinion

Prototypes aren’t always kept secret. Getting the opinions of your potential customers on your prototype can be very important to guide the development process. Performing testing with your prototype is essential and when you can get it into the hands of real potential customers this process is even more valuable.

The more accurate the prototype, the more valuable this feedback is. Refine your design to make it more effective, to meet your customers’ needs more closely, or to be more appealing to them.

Quick & Cost-Effective

CNC lathes are a more-cost effective and a faster prototyping process than many others. Further, it enables you to get critical feedback earlier in the design process, which also saves you from the cost of these reworks after limited runs or other design milestones. The earlier you can adjust your product, the less it costs you to do so.

Make Adjustments to Your Product

Most products will change dramatically from  their initial prototype to when they are released to the market. Making these adjustments is always necessary, but your success is somewhat determined by how quickly and how well you can make these adjustments. With greater detail, including the right material and tight tolerances, prototypes made with CNC lathes have more accuracy which helps you understand the product better. Your testing, including consumer testing, will be more accurate and faster, which ultimately saves you time.

their initial prototype to when they are released to the market. Making these adjustments is always necessary, but your success is somewhat determined by how quickly and how well you can make these adjustments. With greater detail, including the right material and tight tolerances, prototypes made with CNC lathes have more accuracy which helps you understand the product better. Your testing, including consumer testing, will be more accurate and faster, which ultimately saves you time.

Using a CNC lathe will help you make the most of the prototyping process and ultimately get you a better product.

Get in touch to learn how we can get you the CNC prototype your business needs.