Creating custom sheet metal enclosures involves a detailed and structured process that transforms your design concepts into functional, durable products. You’ll find that turning an idea into a precise enclosure requires careful planning, skilled fabrication, and thorough quality control. Understanding the steps involved—from initial consultation through prototyping to full production—can help you make informed decisions and ensure your project meets design and performance expectations.

Initial Consultation & Design Review

The process starts with a comprehensive consultation focused on your specific requirements. Your design specifications, operational needs, and end-use applications are discussed in detail to create a clear project scope. This collaboration ensures that every aspect of your enclosure, from dimensions to materials, aligns with your goals and performance criteria. It also allows for early identification of potential challenges and measurement of feasibility, which helps streamline later stages. This stage is critical for setting the foundation for a successful fabrication process.

Design review involves analyzing your drawings or CAD models to optimize manufacturability without compromising your design intent. Experts examine factors such as material thickness, bend radii, and assembly points to improve production efficiency and part longevity. This assessment also includes considerations for ventilation, cable routing, and mounting features unique to your application. Adjustments discussed during this phase prevent costly rework during prototyping or production. Engaging in this thorough review process assures better alignment between your product’s function and the final fabricated enclosure.

Your active involvement during design review is invaluable in refining specifications and selecting appropriate fabrication techniques. Any modifications suggested can be quickly incorporated, allowing for a smooth transition to prototyping. This ensures the prototype accurately represents the intended final product, accelerating development timelines. By prioritizing collaboration and precision early on, the process minimizes surprises during fabrication and testing.

Prototyping with Precision Equipment

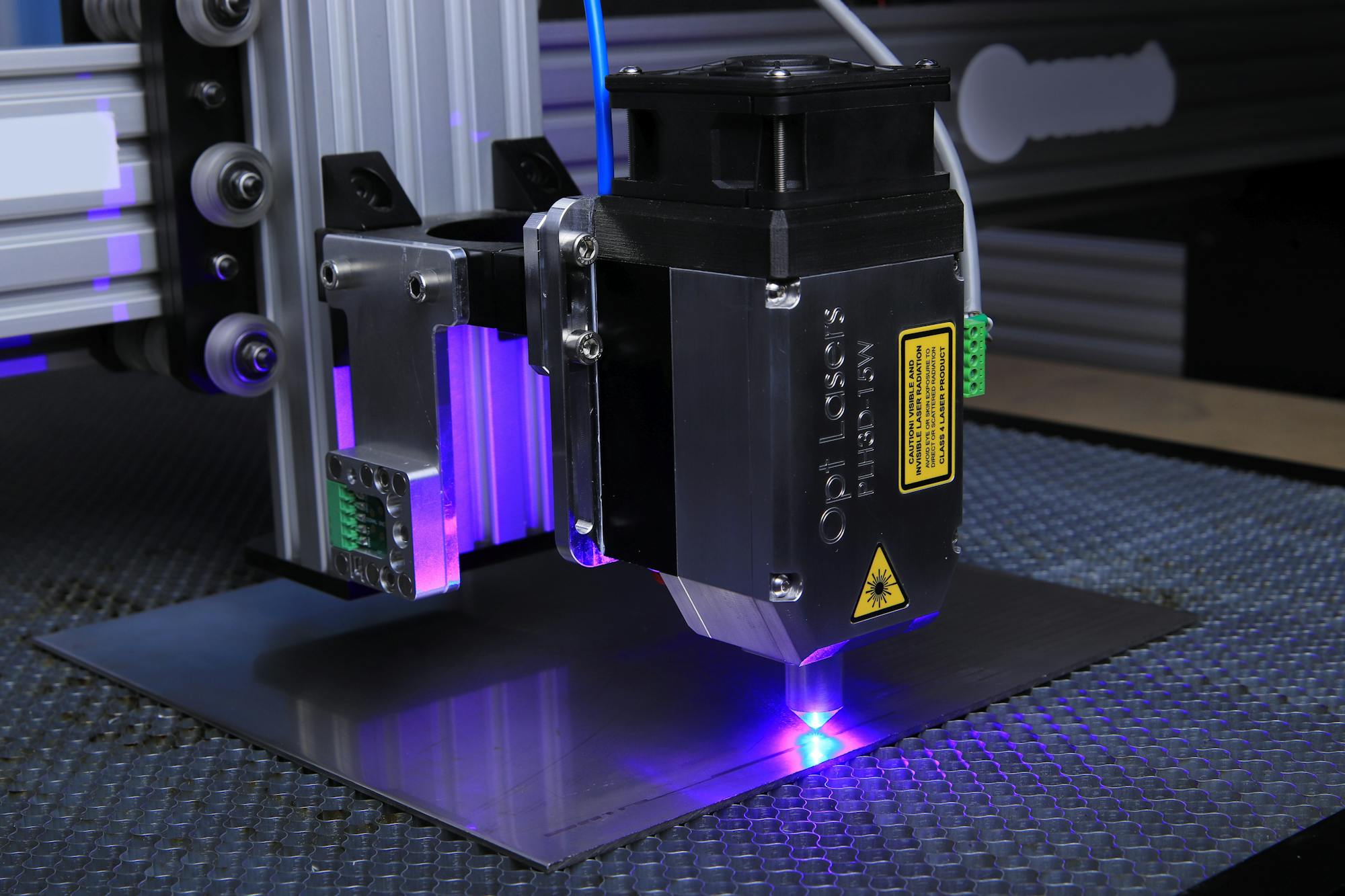

Once the design is finalized, prototypes are produced using advanced machinery like the Amada Ventis 3015 AJ fiber laser. This equipment delivers precise cutting and detailed features essential for testing fit and function. Prototypes serve as tangible models to verify that dimensions meet your design and the enclosure integrates properly with components. You gain the opportunity to inspect the prototype thoroughly and provide feedback before committing to full production. Rapid turnaround of prototypes makes it easier to iterate designs efficiently.

Once the design is finalized, prototypes are produced using advanced machinery like the Amada Ventis 3015 AJ fiber laser. This equipment delivers precise cutting and detailed features essential for testing fit and function. Prototypes serve as tangible models to verify that dimensions meet your design and the enclosure integrates properly with components. You gain the opportunity to inspect the prototype thoroughly and provide feedback before committing to full production. Rapid turnaround of prototypes makes it easier to iterate designs efficiently.

The precision laser cutting technology used for prototyping minimizes material waste and maintains tight tolerances. This level of accuracy helps replicate real-world conditions your enclosure will face in operation. Testing the prototype assists in identifying any design flaws, interference issues, or assembly difficulties early. Adjustments can be made without impacting large-volume manufacturing costs. Producing a prototype that meets your expectations builds confidence in moving forward.

Beyond cutting, the prototype phase includes initial forming and assembly to simulate the finished enclosure. This hands-on assessment allows you to evaluate structural integrity, access to ports, and overall ergonomics. Fabricating prototypes in-house maintains quality control and accelerates evaluation cycles. Your input remains central throughout, ensuring the prototype fulfills both functional and aesthetic requirements.

Production Scaling & Fabrication Capabilities

Approval of the prototype triggers full production scaling, where consistency and efficiency become paramount. Skilled operators employ CNC machining centers alongside manual equipment for cutting, bending, and forming sheet metal enclosures. This combination caters to varying production volumes while maintaining dimensional repeatability. The process integrates automated and manual steps tailored to your project’s complexity and timelines. This flexibility supports small runs as well as large batch manufacturing.

Automated CNC machines handle high-precision cutting and complex shapes, increasing throughput while reducing errors. Manual forming and finishing complement these operations by addressing details that require specialized attention. This hybrid approach ensures each enclosure matches the prototype’s standards while optimizing costs and lead times. Production capacity adjusts to your delivery schedule and volume requirements without compromising quality.

Material handling and fabrication expertise during this stage safeguard against common issues such as warping, misalignment, or surface defects. Regular process monitoring and maintenance of equipment secure stable output quality. The ability to efficiently scale from prototype to production means you receive high-quality sheet metal enclosures on demand, ready to integrate seamlessly into your product line.

Quality Assurance & Finishing

Every completed enclosure undergoes rigorous quality control to verify compliance with specifications and performance standards. Dimensional inspections, structural tests, and surface evaluations confirm that the finished product meets your expectations. This scrutiny helps prevent defects that could impact assembly or long-term reliability. Maintaining traceability throughout the fabrication process contributes to consistent quality outcomes.

Finishing services such as welding, forming, and hardware installation take place on-site, allowing close supervision of fit and finish. Welding expertise ensures robust joints that maintain enclosure integrity without distortion. Forming processes finalize shapes and features according to design demands, while in-house hardware integration provides precise mounting of fasteners, hinges, or electronic components. This comprehensive finishing maximizes functional and aesthetic value.

Handling all finishing steps internally enhances responsiveness and reduces lead times for adjustments or rework. The cohesive quality assurance framework supports delivering sheet metal enclosures that stand up to rigorous operational conditions. You’ll find that these meticulous practices foster trust and satisfaction with the final product’s durability and performance.

Bringing It All Together

Custom Sheet Metal Enclosures: Prototype to Production in Oxnard

Your sheet metal enclosure project benefits from a clear, methodical approach starting with detailed consultation and design validation. Precision prototyping with advanced equipment gives you tangible proof of concept to refine and approve. Scaling to full production employs both automated and manual fabrication resources, ensuring reliability and efficiency. Finally, comprehensive quality control and finishing bring each enclosure up to the highest standards.

This structured process positions your project for success by balancing customization with manufacturing expertise. To explore how custom sheet metal enclosures can meet your exact needs, contact Laserworx Manufacturing. Discuss your project details, request a quote, or learn more about precision fabrication capabilities that turn your designs into production-ready parts with accuracy and care.